Mr-Sandman

Solar Enthusiast

- Joined

- Dec 28, 2021

- Messages

- 351

So after about 1 year of service this CHTAIXI DZ47Z-63 series 32 amp breaker failed. I would like to understand why.

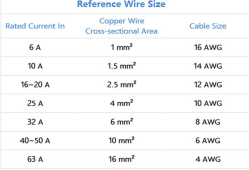

The breaker that failed is a 500v 32 amp DC breaker. This breaker is used as an indoor disconnect for a PV array into the Solar Charge Controller. The Solar panels feed into the TOP of the breaker using 8 gauge wire and the SCC is hooked to the bottom of breaker. There are (4) 455w solar panels in (2) strings making for about 90v and 20 amps max. There are no shorts and the breaker was found NOT tripped as shown in picture, with no connectivity going thru it anymore. Only the positive side failed, no signs of anything wrong with negative side. The 8 gauge cable on the burnt end was still secure and tight "no Ferrules used, but solid connection". The breaker and cable next to the breaker got extremally hot, no other connection in the circuit show signs of heat.

Thoughts on what went wrong here? Did I hook something up wrong? Maybe a bad breaker?

The breaker that failed is a 500v 32 amp DC breaker. This breaker is used as an indoor disconnect for a PV array into the Solar Charge Controller. The Solar panels feed into the TOP of the breaker using 8 gauge wire and the SCC is hooked to the bottom of breaker. There are (4) 455w solar panels in (2) strings making for about 90v and 20 amps max. There are no shorts and the breaker was found NOT tripped as shown in picture, with no connectivity going thru it anymore. Only the positive side failed, no signs of anything wrong with negative side. The 8 gauge cable on the burnt end was still secure and tight "no Ferrules used, but solid connection". The breaker and cable next to the breaker got extremally hot, no other connection in the circuit show signs of heat.

Thoughts on what went wrong here? Did I hook something up wrong? Maybe a bad breaker?

Last edited: