mikeinnyc

New Member

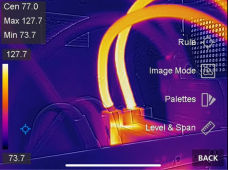

use n/c alert trigger. You can also have an annoying repeating robotic Voice phone call "The roof is on fire," with sms and email. If that's running in your house you better have these alerts. I'd be happy to share my brain so that you live another day.Ya I'm not willing to just slap another breaker in there and call it good. I do consider myself lucky, as this system is inside my home.

I do have a smoke detector mounted directly above this system that sends push notification directly to me. It did NOT alert. I never smelt smoke and honestly I'm not even sure when this happened, I just noticed reduced output and found this string of panels not working.

The breakers are sealed pretty well in the plastic enclosure you see in the first pic. I think the breaker housing would have contained any smoke pretty well. I do not smell any burnt smell in the room either.

Automate your work today | Zapier

Workflow automation software for everyone. Zapier automates your work across 6,000+ app integrations, so you can focus on what matters.

The Roof is on fire some humor for the dinosaurs

Last edited: