You can run multiple charger/converters in parallel. Is the power going to a truck camper or a trailer?

The shorter the distance the easier/less expensive this will be. To get high amp charging to either a truck camper or a trailer can be quite expensive. The cost of cabling is usually what limits the amperage. 80 amps of 24 volt charging is 160 amps of 12 volt input. It's probably worse than that because the input amps are almost always higher than the output amps when the voltage needs to be increased (like from 12.8 to 14.2). For example, a 20 amp charger (12 volt input to 12 volt output) may require 25 amps from the alternator. You have to take into consideration the higher input amps in your design.

To control the cost of cable, as well as the cost of the charger devices, we tend to recommend lower amp charging rates. For my RV, if I were to use the charge from the 7-pin circuit on my tow vehicle (also an F-350 6.7L w/ 397 amp charging system), I would aim for no more than 20 charge amps. To do that I would use one of the chargers from Victron:

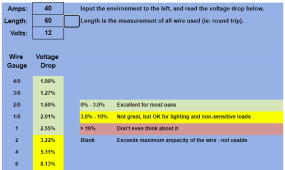

To get any more charge amps than that, I would have to run dedicated cabling. Let's say I wanted 40 amps. For my setup, the distance from alternator to charger (located close to the RV's LiFePO4 battery) would be 60' round trip. I use a conservative voltage of 12.0 volts as a worst case number. Using the

Wire Size Calculator at Bay Marine Supply I get the following output:

View attachment 137804

2 AWG cable isn't large enough. We want the voltage drop to be under 3%. The more the voltage drops, the more amps the charger will pull. So we want the voltage drop as small as possible, within reason. 1 AWG is the smallest I would go with. 60' of 1 AWG cable from

TEMCo Industrial would run about $157. That's welding wire, which is what I prefer to use.

However, Victron doesn't make a 12-12 charger suitable for this situation rated for 40 amps. The highest they have is 30 amps. The highest 12-24 charger is rated for only 15 amps.

If you want 30 amps of 24 volt charging, buy two chargers and run two sets of cable. The cable alone is going to cost over $300 if you use two chargers.

In general, the charger is supposed to be located as close to the target battery as possible. For that reason, the 12 volt current is run almost the entire length of the cable. If we could put the charger next to the alternator then the current would be running at 24 volts and we could use smaller wire. 4 AWG would work. However, you really don't want to put the charger in the engine compartment due to heat and moisture. Plus that violates our preference for placing the charger close to the target battery.