You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4 MWh SRNE ASF48100U200-H 10kw.

- Thread starter 42OhmsPA

- Start date

42OhmsPA

What's in a title?

Wonder if this is the 12KW version? not available for the US yet...

Kinda makes me want to consider a transformer again....

Who was looking for a 3 phase inverter recently?

800VOC... Most could run 16S strings...

www.srnesolar.com

www.srnesolar.com

Kinda makes me want to consider a transformer again....

Who was looking for a 3 phase inverter recently?

800VOC... Most could run 16S strings...

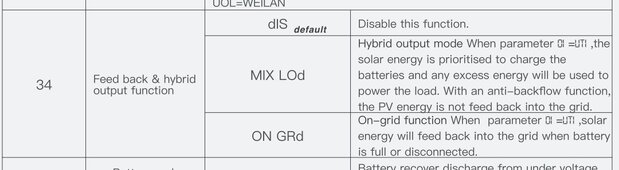

8kw 10kw 12kw Storage Inverter

ASF series is a new type of solar energy storage inverter control inverter integrating solar energy storage & utility charging and energy storage, AC sine wave output.

42OhmsPA

What's in a title?

You need a bigger battery pack ?View attachment 190578

Tested to see if it would trip. Itll just switch back to grid. Very very impressive

You pulled ~225a off a 35% battery and the inverter didn’t mind?View attachment 190578

Tested to see if it would trip. Itll just switch back to grid. Very very impressive

Sigh, tell me why I could see the numbers in the orange screenshot changing (like they do when on the SRNE site and it auto scrolls to the next specs)Wonder if this is the 12KW version? not available for the US yet...

Kinda makes me want to consider a transformer again....

Who was looking for a 3 phase inverter recently?

800VOC... Most could run 16S strings...

View attachment 1907508kw 10kw 12kw Storage Inverter

ASF series is a new type of solar energy storage inverter control inverter integrating solar energy storage & utility charging and energy storage, AC sine wave output.www.srnesolar.com

I need to stop refreshing their site to see what’s new ?

Bms didn't shut down. Inverter went into that grid over protection switch. mode. forget the name. I'm up over 30kwh nowYou need a bigger battery pack ?

YesYou pulled ~225a off a 35% battery and the inverter didn’t mind?

Last edited:

That’s awesome!Bms didn't shut down. Inverter went into that grid over protection switch. mode. forget the name.

Yes

42OhmsPA

What's in a title?

Kenny_

Solar Addict

Same, not/never enabled and didn't know it existed til pointed out by @42OhmsPAIt has the option to sell excess loads to the grid, I've never turned it on. I've had zero issues with it disabled. I am not aware of any external CT.

View attachment 190846

How does the anti backflow work if there are no ct's?It has the option to sell excess loads to the grid, I've never turned it on. I've had zero issues with it disabled. I am not aware of any external CT.

View attachment 190846

It most likely does not. Don't think any of us have tested this, howeverHow does the anti backflow work if there are no ct's?

42OhmsPA

What's in a title?

If I remember right all of your packs are made up of different parts right? So wouldn't the soc vary from that?I'm throwing in the towel on getting SOC to match....

Just going to keep running it...

View attachment 190920

Kenny_

Solar Addict

That's pretty much where I am as well this SOC stuff is kinda nebulous...I'm throwing in the towel on getting SOC to match....

Just going to keep running it...

View attachment 190920

Now it's Battery/Pack #4 that's lagging .. all different SOCs but all the same voltages...

42OhmsPA

What's in a title?

2 packs are 230ah cellsIf I remember right all of your packs are made up of different parts right? So wouldn't the soc vary from that?

1 pack is 305ah cells.

All 3 are using JBD contactor BMS, 2 200A, 1 300A (with different model versions and firmware)....

All BMS settings / setpoints (except capacity, cycle count and name ) are the same).

I think it is due to the 305ah cells being out of balance... The lowest cell never triggers the full set point... I'll find out come summer when they are normally floating by noon, sooner if cell prices drop and I order 32+ more and a handful of JKs...

Last edited:

marionw

Solar Enthusiast

Most batteries do not actually report SOC. This is a calculated value by the monitoring software (or inverter) using two values reported by the battery BMS:

SOC = Remaining Capacity / Full Capacity

Full capacity is a constant in the battery and is it's designed AH, i.e. 100AH

Not sure how the BMS calculates remaining capacity.

A master (Inverter, SA or monitoring software such as SOKTools or PbmsTools) sends an 0x42 (Pack analog information) command to the battery and the battery responds with a number of items including:

1. Each cell voltage

2. Whether the cell is in Bal, OVP or UVP

3. Up to six temperature values including MOSFET and Ambient temperatures.

4. Batteries "Full Capacity".

5. Batteries "Remaining Capacity".

The SOKTool or Pbmstool will display "FullCapacity" and "RemainingCapacity". The displayed SOC is a calculated value in the software based on these two values reported by the battery (SOC = Remaining Capacity / Full Capacity)

To verify this you can look at the Pylontech, PACE or Narada BMS protocol documentation.

SOC = Remaining Capacity / Full Capacity

Full capacity is a constant in the battery and is it's designed AH, i.e. 100AH

Not sure how the BMS calculates remaining capacity.

A master (Inverter, SA or monitoring software such as SOKTools or PbmsTools) sends an 0x42 (Pack analog information) command to the battery and the battery responds with a number of items including:

1. Each cell voltage

2. Whether the cell is in Bal, OVP or UVP

3. Up to six temperature values including MOSFET and Ambient temperatures.

4. Batteries "Full Capacity".

5. Batteries "Remaining Capacity".

The SOKTool or Pbmstool will display "FullCapacity" and "RemainingCapacity". The displayed SOC is a calculated value in the software based on these two values reported by the battery (SOC = Remaining Capacity / Full Capacity)

To verify this you can look at the Pylontech, PACE or Narada BMS protocol documentation.

Zwy

Emperor Of Solar

I run 3 280's and one battery comprised of 304's. One of the 280's is half 280K and the other half 280N. Top 2 batteries are 280N's.If I remember right all of your packs are made up of different parts right? So wouldn't the soc vary from that?

The 280K were bargain basement from Amy as I needed 8 cells. I originally ordered 40 cells, planned on 32 for the house bank and 8 for 2 12V trolling batteries. I ended up buying some Zoom's for the boat, hence the need for 8 cells. These were cheap, not batched and I should have known better but hey, what is life without a challenge?

One is a major runner, then falls below when charging ceases. 3 more do run some, and 3 are laggards. Remaining fall in between. The 280N's on that battery hold great balance.

I bought these for $107 each when batched were about $160. These do work though well though, just takes some balance at the top and actually hold on the bottom very well including the runner.

I do have one of the 304's (purchased as grade B from 18500) that is always the low cell out of 64 cells.

I do run all cables to busbars down the sides of the cabinet all the same length. I run a nickel plated busbar down each side that I plated myself comprised 1/4" x 1.25" copper.

42OhmsPA

What's in a title?

I'm definitely using one big main busbar on my next expansion.I do run all cables to busbars down the sides of the cabinet all the same length. I run a nickel plated busbar down each side that I plated myself comprised 1/4" x 1.25" copper.

I'm happy with my current DIY mini cabinet busbar but after this winter, so far, I need a lot more battery.

I'm still trying to find a large cabinet, I've contemplated the idea of finding an old walk in freezer and using it as power room... Weld up some simple racking with angle and C channel to hold stacks of cells...

Tiny space heater would keep the cells happy and I could save a ton (or more) of coal running the basement colder. I'd also save on electricity taking some load off the mini split.... Yea, I really like that idea; hell I could even relocate it to the unattached garage.

Similar threads

- Replies

- 14

- Views

- 348

- Replies

- 445

- Views

- 14K

- Replies

- 2K

- Views

- 50K

- Replies

- 69

- Views

- 5K

- Replies

- 56

- Views

- 4K