As long as sufficient heat difference exists.A Sterling engine driving a Sterling Heat Pump requires no external source of electrical/mechanical energy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Storing heat in sand?

- Thread starter Guda

- Start date

McKravitts

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 536

That's very true.As long as sufficient heat difference exists.

You actually have two delta T's that need to be satisfied. The temperature difference that drives the sterling heat engine and the the temp difference that the het pump must deliver.

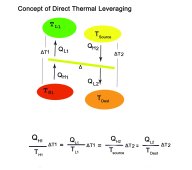

Years ago I developed a simplified method of determining required heat flows for an ideal sterling heat engine powering an ideal heat pump.

At the time there was nothing on the market that was even close to delivering the efficiency necessary.

For what it's worth here's a copy/paste of a brief description.

I did a sample calculation at the end.

Of course the calculations must be adjusted for the inefficiencies on both ends of the lever.

In the thermal leverage diagram, the red oval represents a large source of heat at a temperature of TH1,

The green oval represents a large heat sink at a temperature TL1. TH1 must be higher than TL1..

These two source/sinks could be the surrounding atmosphere, the earth, a large body of water, an object heated by the sun, a source of ground water etc.

We tap into the natural heat flow from TH1 to TL1 and leverage that flow to pump heat from the yellow body Tsource to the orange body Tdest.

Example:

A group of picnickers wish to keep a refrigerated container at 45 degrees throughout the day.

The air temperature is 90 degrees F. There is a small stream flowing through their picnic area with a constant temperature of 60 degrees F. They know that the refrigerated container will require about 250 BTU/hr to stay at 45 degrees.

To use the above formula temperatures must be converted to an absolute scale (one where 0 is absolute 0). For calculation purposes we will use the Rankine scale.

The conversion formula is ﹾR= ﹾF + 459.67

They’ll use the air as TH1, The stream will provide the sink TL1 and and also Tdest.

The refrigerated container is Tsource which is set 45ﹾ F

Converting all temperatures to rankine we get:

TH1 = 549.67 ﹾR TL1= 519.67 ﹾR

Tsource = 504.67 ﹾR Tdest = 519.67 ﹾR

ΔT1 = 30 ﹾR and ΔT2 = 15 ﹾR

QH2 is 250 BTU/hr

QH2 divided by Tsource times ΔT2 equals 62.5

QH1 can be calculated by simple algebra QH1 =( 62.5 *549.67) /30.

QH1 = 1145.15 BTU/hr And QL1 = 1082.65 BTU/hr

Result: They’ll need to absorb about 1145 BTU/hr from the air and dump 1083 into the creek in order to get 250 BTU/hr of cooling at 45 ﹾF

The benefit is that it’s a free 250 BTUs/hr.

This can be improved by increasing TH1 by using a solar absorber.

For example by using a solar absorber at 120 ﹾF (579.67 ﹾR) for TH1, the amount of heat needed for QH1 is reduced to only 622.57 BTU/hr which can be achieved with a panel of about 2.5 square feet. The solar absorber could be nothing more than a flat black piece of metal connected to something that can transmit the heat into the input of the lever.

To date, as far as I know there is nothing commercially available that can be used for a “Thermal Lever”.

The most promising devices available are built around the Stirling engine. Stirling engines are already being used in Arizona to achieve solar efficiency of about 30 %.

The Stirling engine has a cousin called a Stirling heat pump. By coupling a Stirling engine to a Stirling heat pump a thermal lever can be created.

There is an excellent Utube video describing the process and the device

Attachments

MyK3y

Hack

Our biggest electric cost is heating. Our use of electric outside of heating is about 250-300kWh/mo, so not big power users. I was looking for a more efficient way of heating our home. We have 'smart' wall panel heaters - 3x 2400W and 2x 1200W - so running them uses a lot of electric.

I thought that a solar battery is something that is efficient, cheap to implement, safe and robust.

My roughed-out design is:

60L steel drum with sand and one or more 2400W 220V spiral stove element pulled into a cone, buried in the sand, fed direct DC from 2x 445W solar panels (

The 60L drum sits inside a 220L (44 Gallon) drum filled with small river rocks (because I have an unlimited supply) which act as a heat sink, suspend the 60L drum and allow air to flow through from a 12V variable-speed 4" bilge/ventilation inline fan (as used in boats) which is ducted into my lounge. We have a wooden/brick house sitting up on pilings with a decent amount of space underneath to house it all and a short run directly up into the lounge. The lounge faces North, so mounting the panels to the wall right outside is perfect both for connectivity and solar direction.

The reason for the above:

In addition to the sand battery and its components I will set up a control and monitoring system using an ESP32 and some thermocouples and maybe even act as a speed controller for the DC blower. I already have a fully-operational Home Assistant setup which I can use for monitoring and control - I already monitor power & environmentals using ESPs, so have experience integrating such devices.

And, I can get it all up and running for about $50 as a test unit.

The main question is - why tf did I wait until the first week of spring to do this?

I thought that a solar battery is something that is efficient, cheap to implement, safe and robust.

My roughed-out design is:

60L steel drum with sand and one or more 2400W 220V spiral stove element pulled into a cone, buried in the sand, fed direct DC from 2x 445W solar panels (

The 60L drum sits inside a 220L (44 Gallon) drum filled with small river rocks (because I have an unlimited supply) which act as a heat sink, suspend the 60L drum and allow air to flow through from a 12V variable-speed 4" bilge/ventilation inline fan (as used in boats) which is ducted into my lounge. We have a wooden/brick house sitting up on pilings with a decent amount of space underneath to house it all and a short run directly up into the lounge. The lounge faces North, so mounting the panels to the wall right outside is perfect both for connectivity and solar direction.

The reason for the above:

- 60L steel drum and sand - because it's ridiculously cheap. A recycled 60L drum is $10 where I live and river sand is free for the taking down at the river bank.

- The stove element - rather than a tank element, heating wire, etc. is that they're designed to heat to over 750C in air. They are really physically durable - designed to last for years and years being banged by steel pans, are electrically durable for the same reason, and are relatively cheap ($40). Given river sand is almost completely electrically insulating, so I can use physical friction-fit terminals and bare copper wire (copper wire melting point >1000C) run through the sand and with refractory cement 'grommets' through the steel wall

- 220L drum and small river rocks - the rocks make good heat sinks, are insulating for the internal drum, allow decent airflow, are inflammable, and are cheap. I have a lot of leftover glass wool insulation which I would wrap the whole assembly in for further insulation.

- Solar panels running directly to the element removes any losses from DC/AC transformation. I was going to use a spare car battery and cheap solar charge controller (~$20) for 12V supply for the inline fan

- 12V inline bilge blower/fan - again, cheap and reliable. Good ones with decent bearings are designed to run forever in a boat engine room. They draw about 20-30W for 100-150 cu ft/min. A 60AH battery would give 720Wh or 24 hours continuous running

- 445W solar panels - price/performance they're neither cutting edge or expensive - less than NZ$1/W. At noon in winter I was getting ~9A @ ~35V from one panel - enough to get the element to give about 350W of heat at peak. Tossing up whether to go series or parallel. I have two lower-powered (200W) panels which I can use to gain measurements between the two different architectures.

In addition to the sand battery and its components I will set up a control and monitoring system using an ESP32 and some thermocouples and maybe even act as a speed controller for the DC blower. I already have a fully-operational Home Assistant setup which I can use for monitoring and control - I already monitor power & environmentals using ESPs, so have experience integrating such devices.

And, I can get it all up and running for about $50 as a test unit.

The main question is - why tf did I wait until the first week of spring to do this?

Last edited:

MyK3y

Hack

Original concept from this guy:

He's got about 30 vids over 6 months of progressively improved design.

He's got about 30 vids over 6 months of progressively improved design.

Partimewages

Solar Addict

You didn't give an approximate location. You will want to do a heat load calculation and that will give you an idea of what your savings are. What is the plan for rain/cloudy and overnight?Our biggest electric cost is heating. Our use of electric outside of heating is about 250-300kWh/mo, so not big power users. I was looking for a more efficient way of heating our home. We have 'smart' wall panel heaters - 3x 2400W and 2x 1200W - so running them uses a lot of electric.

I thought that a solar battery is something that is efficient, cheap to implement, safe and robust.

My roughed-out design is:

60L steel drum with sand and one or more 2400W 220V spiral stove element pulled into a cone, buried in the sand, fed direct DC from 2x 350W solar panels (

The 60L drum sits inside a 220L (44 Gallon) drum filled with small river rocks (because I have an unlimited supply) which act as a heat sink, suspend the 60L drum and allow air to flow through from a 12V variable-speed 4" bilge/ventilation inline fan (as used in boats) which is ducted into my lounge. We have a wooden/brick house sitting up on pilings with a decent amount of space underneath to house it all and a short run directly up into the lounge. The lounge faces North, so mounting the panels to the wall right outside is perfect both for connectivity and solar direction.

The reason for the above:

- 60L steel drum and sand - because it's ridiculously cheap. A recycled 60L drum is $10 where I live and river sand is free for the taking down at the river bank.

- The stove element - rather than a tank element, heating wire, etc. is that they're designed to heat to over 750C in air. They are really physically durable - designed to last for years and years being banged by steel pans, are electrically durable for the same reason, and are relatively cheap ($40). Given river sand is almost completely electrically insulating, so I can use physical friction-fit terminals and bare copper wire (copper wire melting point >1000C) run through the sand and with refractory cement 'grommets' through the steel wall

- 220L drum and small river rocks - the rocks make good heat sinks, are insulating for the internal drum, allow decent airflow, are inflammable, and are cheap. I have a lot of leftover glass wool insulation which I would wrap the whole assembly in for further insulation.

- Solar panels running directly to the element removes any losses from DC/AC transformation. I was going to use a spare car battery and cheap solar charge controller (~$20) for 12V supply for the inline fan

- 12V inline bilge blower/fan - again, cheap and reliable. Good ones with decent bearings are designed to run forever in a boat engine room. They draw about 20-30W for 100-150 cu ft/min. A 60AH battery would give 720Wh or 24 hours continuous running

- 350W solar panels - price/performance they're neither cutting edge or expensive - less than NZ$1/W. At noon in winter I was getting ~9A @ ~35V from one panel - enough to get the element to give about 350W of heat at peak. Tossing up whether to go series or parallel. I have two lower-powered (200W) panels which I can use to gain measurements between the two different architectures.

In addition to the sand battery and its components I will set up a control and monitoring system using an ESP32 and some thermocouples and maybe even act as a speed controller for the DC blower. I already have a fully-operational Home Assistant setup which I can use for monitoring and control - I already monitor power & environmentals using ESPs, so have experience integrating such devices.

And, I can get it all up and running for about $50 as a test unit.

The main question is - why tf did I wait until the first week of spring to do this?

Mart Hale

New Member

- Joined

- Feb 4, 2020

- Messages

- 182

Yes, I have followed all his videos with great interest.Original concept from this guy:

He's got about 30 vids over 6 months of progressively improved design.

Looking at his temps over 250 degrees in the morning, if nothing else he has created a solar powered cob over or crock pot if he was to put a pot of beans in they would be cooked ;-0

I have completed my most recent project which is to use the extra solar power I have after my battery is charged, I dump that dc power direct from solar panels to the hot water heater element, in series is the thermostat of the hot water heater so once it hits temp, it auto shuts off, it has been working like a dream for the last few months.

MyK3y

Hack

I'll work it the other way - whatever I get will be the heat we will employ.You didn't give an approximate location. You will want to do a heat load calculation and that will give you an idea of what your savings are. What is the plan for rain/cloudy and overnight?

As to overnight - that's the use-case. It's a heat store - overnight is when it does its thing and recharges during the day.

NZ is very sunny, even in winter. The panels will be oriented for winter efficiency - 48deg or so. It would be good to find a use for them during summer. Maybe a Peltier cooler array? We've never had AC - doesn't get that hot.

Beer fridge would be the most useful.

Last edited:

MyK3y

Hack

That's a good system - We have on-call mains-pressure gas hot water - so no water tank.Yes, I have followed all his videos with great interest.

Looking at his temps over 250 degrees in the morning, if nothing else he has created a solar powered cob over or crock pot if he was to put a pot of beans in they would be cooked ;-0

I have completed my most recent project which is to use the extra solar power I have after my battery is charged, I dump that dc power direct from solar panels to the hot water heater element, in series is the thermostat of the hot water heater so once it hits temp, it auto shuts off, it has been working like a dream for the last few months.

I looked at water as a reservoir of heat, but without the existing infrastructure would be much more expensive - sand battery is such a simple and price-effective solution for the temperate climes of the South Pacific.

Where we are in NZ (-40 deg S) has very moderate temperatures - the lowest it got over winter was 5C/40F. Currently we only heat the house for a couple of months - July and August. It would be nice to heat it a bit more often, as we get older and need more comfort. The ability to scale up at moderate cost is appealing.

A sand battery fulfils a lot of criteria, not least of which is the ability for me to do it all myself, as anything 'electrical' requires the attention of a registered electrician at around $180/hr.

We have a wooden house about 4ft up on piles, so I can put the whole shebang underneath the main living room. Short runs for power, ducting and if it proves efficacious, can do the same thing at the other end of the house which we tend to shut up over winter.

The other thing is the fire safety - sand an a 44Gal drum, even under a 90-year-old wooden house is safe. I will put a smoke detector in, just for safety and because I can easily monitor using Home Assistant and because I have literally boxes of microcontrollers and sensors in the shed.

I've just contracted for 5kW of solar and will be using a Nissan Leaf 24kWh battery for storage - Leaf batteries run about $4k second hand, where a new 5kW LiFePo4 battery is $2k (all my prices are NZD - 1 USD is about 1.70) Of course I could use the solar and battery to drive a sand battery but as I said - need to employ an electrician for anything like that, where the DC side I'm allowed to do on my own.

Ideally we would like to get rid of all mains connections and gas - from a 'green' conservation perspective as well as to save money after retirement. May as well do it all now, while I'm working.

Last edited:

MyK3y

Hack

The problem I see with a rocket stove with sand as the medium is insulating the barrel to conserve the heat after burning.I am in process of making my next sand battery. I want to heat it either by solar panels, or by burning trash / wood.... I am looking to figure out how to get that heat trapped into the sand with the rocket stove.

If it was me, I would look at making a heat-pump from the rocket stove to the sand battery using a closed-loop thermosiphon heat transfer, like a copper pipe coil filled with mineral oil, to a corresponding coil in the sand battery. The efficiency is about 100% - depending on how well you insulate the pipes between the rocket stove and the battery case. Fibreglass sheathing holding rockwool or glass-wool round the pipe and wrapped in foil is pretty darned effective.

Most closed-loop solar hot water thermosiphon systems use mineral oil. Safe, inflammable, minimal expansion, high-heat load-carrying ability, low viscosity so the siphon is efficient.

Like this, but replace the solar collector with rocket stove: https://www.level.org.nz/fileadmin/downloads/Energy/LevelDiagram33.pdf

One advantage to living where liquor stills are readily available and legal, is the ease of access to off-the-shelf copper coils

Last edited:

orangezero

New Member

- Joined

- Sep 20, 2020

- Messages

- 93

MyK3y, is this inside your house or underneath and outside?

I was leaning towards water for storage because I can keep a tank in my basement, then use a dc water pump to circulate hot water through some pex tubing. I was going to mount the pex tubing underneath my wood floor, then attach insulation underneath that. When I'm in my basement I'll look up and see the insulation in the ceiling of the basement. The heat will mostly rise up and warm up my entire floor upstairs. No need to add registers or anything upstairs really.

I've done a few airbnbs that had radiant floor heating and it was nice. I think you can replicate most of those features without huge expenditures if you plan it out. Pex tubing isn't that much and people sell their excess for cheap. I can find rigid insulation for between my floor joists used for cheap. No one in my home would probably even know I had it. And it would be pretty simple to remove if I sold the house.

In your case, if you have access under the floor it may be something to consider. I was always leary of water circulating in my house, all the plumbing fixtures, manifolds, etc... but the reality is to heat one or two rooms it is just a few hundred feet of tubing. The pump could literally be stored in the water tank and after it cycles through the pex it dumps back in the same tank. Your "water tank" could just be sitting next to your sand tank and rocks.

I was leaning towards water for storage because I can keep a tank in my basement, then use a dc water pump to circulate hot water through some pex tubing. I was going to mount the pex tubing underneath my wood floor, then attach insulation underneath that. When I'm in my basement I'll look up and see the insulation in the ceiling of the basement. The heat will mostly rise up and warm up my entire floor upstairs. No need to add registers or anything upstairs really.

I've done a few airbnbs that had radiant floor heating and it was nice. I think you can replicate most of those features without huge expenditures if you plan it out. Pex tubing isn't that much and people sell their excess for cheap. I can find rigid insulation for between my floor joists used for cheap. No one in my home would probably even know I had it. And it would be pretty simple to remove if I sold the house.

In your case, if you have access under the floor it may be something to consider. I was always leary of water circulating in my house, all the plumbing fixtures, manifolds, etc... but the reality is to heat one or two rooms it is just a few hundred feet of tubing. The pump could literally be stored in the water tank and after it cycles through the pex it dumps back in the same tank. Your "water tank" could just be sitting next to your sand tank and rocks.

MyK3y

Hack

Underneath and outside.MyK3y, is this inside your house or underneath and outside?

I was leaning towards water for storage because I can keep a tank in my basement, then use a dc water pump to circulate hot water through some pex tubing. I was going to mount the pex tubing underneath my wood floor, then attach insulation underneath that. When I'm in my basement I'll look up and see the insulation in the ceiling of the basement. The heat will mostly rise up and warm up my entire floor upstairs. No need to add registers or anything upstairs really.

I've done a few airbnbs that had radiant floor heating and it was nice. I think you can replicate most of those features without huge expenditures if you plan it out. Pex tubing isn't that much and people sell their excess for cheap. I can find rigid insulation for between my floor joists used for cheap. No one in my home would probably even know I had it. And it would be pretty simple to remove if I sold the house.

In your case, if you have access under the floor it may be something to consider. I was always leary of water circulating in my house, all the plumbing fixtures, manifolds, etc... but the reality is to heat one or two rooms it is just a few hundred feet of tubing. The pump could literally be stored in the water tank and after it cycles through the pex it dumps back in the same tank. Your "water tank" could just be sitting next to your sand tank and rocks.

The cost for a water-based system far exceeds that of ducted air sand battery and it is a whole lot more work. Our whole underside of the house is insulated using between-joist rockwool about a foot thick then covered in a heavy PVC membrane stapled to every joist. You would need to take all that out.

I am pretty happy with a sand battery and ducted warm air. The sand battery itself is about $50 and $40 of that cost I already have. All I really need is a 44Gal drum and they're $10. To make a test-bench working system I would need an inline fan and a floor duct kit - $150-200.

Dont assume 'Pex tubing isn't that much' - we are an island, remote from anywhere, and things are expensive here. Anything plumbing related is expensive.

Edit: just checked - 150ft of 1/2" is $170 (well, 50M of 20mm, but you guys don't do metric). For the same money in the US you get 600ft - 4x the length or 1/4 of the price.

And while we're talking prices - we pay > NZ$1/W for premium Mono/half-cut PV panels which is hella competitive with the US - but then we pay through the nose for inverters and electricians to install them.

The 445W panels I just got priced are NZ$350/panel for Trina Vertex S+ - USD$205. I can't find them for anything like that in the US.

Last edited:

Mart Hale

New Member

- Joined

- Feb 4, 2020

- Messages

- 182

The problem I see with a rocket stove with sand as the medium is insulating the barrel to conserve the heat after burning.

If it was me, I would look at making a heat-pump from the rocket stove to the sand battery using a closed-loop thermosiphon heat transfer, like a copper pipe coil filled with mineral oil, to a corresponding coil in the sand battery. The efficiency is about 100% - depending on how well you insulate the pipes between the rocket stove and the battery case. Fibreglass sheathing holding rockwool or glass-wool round the pipe and wrapped in foil is pretty darned effective.

Most closed-loop solar hot water thermosiphon systems use mineral oil. Safe, inflammable, minimal expansion, high-heat load-carrying ability, low viscosity so the siphon is efficient.

Like this, but replace the solar collector with rocket stove: https://www.level.org.nz/fileadmin/downloads/Energy/LevelDiagram33.pdf

One advantage to living where liquor stills are readily available and legal, is the ease of access to off-the-shelf copper coils

I have bought a pump already for my setup that can deal with high heat. This will be built outside so I can design it as I want. I am thinking more to a design of a cob oven with either a TLUD or a rocket stove inside....

Have you looked into Nicrome wire?Original concept from this guy:

He's got about 30 vids over 6 months of progressively improved design.

I had an idea of taking heating elements from old stoves at the dump, or..... from dish washers. I would like to test them with solar panels.

MyK3y

Hack

Stove elements are basically nichrome wire, inside a toughened housing.

In ~40 years of home ownership I can't ever remember actually replacing a stove element. Certainly the 5 or so years we occupied various houses I never needed to but the subsequent owner may have needed to.

They are designed to run off 240V vs my implementation at ~60V should increase lifespan. At ~$40 each for a 2400W element, given the ease of implementation, it's almost a no-brainer.

Using the 'cone method' (disassemble the frame and pull the element into a cone shape) it's possible to stack multiple elements inside the sand to increase power, if needed.

I did see one where he mixed carbon black (powdered activated charcoal) with sand to make the sand itself resistant but conductive. Put power in and the sand heats itself through resistance. That's how the big Finnish sand battery works and that's the trick with getting the chemistry right.

This is a quick experiment with carbon black, sand and a piece of copper pipe.

Experimenting with the mix to get the required resistance and, thus, determine the rate you can charge and store.

But, I'm all for an easy life and can't see why reinvent the wheel by experimenting when I know exactly how much power I will get from an off-the-shelf element at a specific voltage.

I spent last night downloading the solar profile from NIWA (NZ water and air agency) for panels oriented from 30deg to 70deg. With a bit of spreadsheet trickery, I found the sweet spot for Autumn/Winter/Spring (May to September) was 65deg - at that angle I get the most power throughout the day. https://solarview.niwa.co.nz

The Boss has given me the go-ahead to make a prototype so I will add a couple of extra panels to our new solar installation and get cooking.

I'm looking at buying an EV battery that has hit 70% - so not good for driving any distance - and will be using a new technique to use the battery in-situ, as a 450V pack, rather than breaking it down and creating a 24/48/96V pack. The advantages of this are that it retains the original BMS which is controlled by Can-Bus, less losses through rectification (only ~2% loss dropping from 450V to 240V, vs ~8% loss from 24V to 240V), weatherproof and safe, uses original OEM cables

My good friend use the same pack, but broke it down to 48V. He spent about a week breaking it down, then had to build a battery frame, make up connecting buses, cables, etc. and had a lot of crap to get rid of at the dump afterwards.

From monitoring his system over a couple of years, his battery capacity has actually returned due to the more gentle charge/discharge and BMS setup. He's drawing ~15-20A peak vs 120A when driving

I can pick up a 65-70% Nissan 24kWh battery pack for ~$3000.

I did think about using the solar to charge the sand battery, but am concerned that I will end up making it too hot. Looking at the guy in the desert, he's getting 500C at ~60V. That's more than enough for house heating. Easier to increase the capacity by adding more sand and an extra element than coping with the insurance company denying my claim after I burn the house down.

I've bought some thermocouples to measure the temps at various points in the sandbatt. They are good to >1200C. A K-type thermocouple and associated amplifier, an ESP8266 and a bit of wire runs less than $10. I can put 3 thermocouples on one ESP which would probably be the setup - outside skin, top and inside the coil as measurement points. Using ESPHome that natively integrates with Home Assistant - it reads as unavailable/0C right now because there is no attached thermocouple and it's not plugged in, but as soon as I powered it up the system found it and published the sensor. Really easy to implement.

In ~40 years of home ownership I can't ever remember actually replacing a stove element. Certainly the 5 or so years we occupied various houses I never needed to but the subsequent owner may have needed to.

They are designed to run off 240V vs my implementation at ~60V should increase lifespan. At ~$40 each for a 2400W element, given the ease of implementation, it's almost a no-brainer.

Using the 'cone method' (disassemble the frame and pull the element into a cone shape) it's possible to stack multiple elements inside the sand to increase power, if needed.

I did see one where he mixed carbon black (powdered activated charcoal) with sand to make the sand itself resistant but conductive. Put power in and the sand heats itself through resistance. That's how the big Finnish sand battery works and that's the trick with getting the chemistry right.

This is a quick experiment with carbon black, sand and a piece of copper pipe.

Experimenting with the mix to get the required resistance and, thus, determine the rate you can charge and store.

But, I'm all for an easy life and can't see why reinvent the wheel by experimenting when I know exactly how much power I will get from an off-the-shelf element at a specific voltage.

I spent last night downloading the solar profile from NIWA (NZ water and air agency) for panels oriented from 30deg to 70deg. With a bit of spreadsheet trickery, I found the sweet spot for Autumn/Winter/Spring (May to September) was 65deg - at that angle I get the most power throughout the day. https://solarview.niwa.co.nz

The Boss has given me the go-ahead to make a prototype so I will add a couple of extra panels to our new solar installation and get cooking.

I'm looking at buying an EV battery that has hit 70% - so not good for driving any distance - and will be using a new technique to use the battery in-situ, as a 450V pack, rather than breaking it down and creating a 24/48/96V pack. The advantages of this are that it retains the original BMS which is controlled by Can-Bus, less losses through rectification (only ~2% loss dropping from 450V to 240V, vs ~8% loss from 24V to 240V), weatherproof and safe, uses original OEM cables

My good friend use the same pack, but broke it down to 48V. He spent about a week breaking it down, then had to build a battery frame, make up connecting buses, cables, etc. and had a lot of crap to get rid of at the dump afterwards.

From monitoring his system over a couple of years, his battery capacity has actually returned due to the more gentle charge/discharge and BMS setup. He's drawing ~15-20A peak vs 120A when driving

I can pick up a 65-70% Nissan 24kWh battery pack for ~$3000.

I did think about using the solar to charge the sand battery, but am concerned that I will end up making it too hot. Looking at the guy in the desert, he's getting 500C at ~60V. That's more than enough for house heating. Easier to increase the capacity by adding more sand and an extra element than coping with the insurance company denying my claim after I burn the house down.

I've bought some thermocouples to measure the temps at various points in the sandbatt. They are good to >1200C. A K-type thermocouple and associated amplifier, an ESP8266 and a bit of wire runs less than $10. I can put 3 thermocouples on one ESP which would probably be the setup - outside skin, top and inside the coil as measurement points. Using ESPHome that natively integrates with Home Assistant - it reads as unavailable/0C right now because there is no attached thermocouple and it's not plugged in, but as soon as I powered it up the system found it and published the sensor. Really easy to implement.

Attachments

Last edited:

MyK3y

Hack

No matter how you fire it, you're going to need a way of storing the heat in sand and insulating it so you don't lose all the heat - how will you do that?I am thinking more to a design of a cob oven with either a TLUD or a rocket stove inside....

Maybe some of you saw David Poz build a water tank that holds 3 days of hot water . My concept it to use sand instead for a few reasons. I think a sand tank would have no maintenance & last for ever. It would not be a possible source of humidity &/or mold. Sand can get hotter than water. No leaks.

How to plumb all that is where I am going to need some advice. Main question is how do I circulate the water (yes copper coil)? But how do I plumb to use the same water to heat the mass & then get that heat out when I need it. My best guess is some kinda valve system. Maybe I should watch Davids video again lol. But I'd also like to know what ppl think of the sand.

I can share what people do here when we are talking about a storage tank for a lot of energy - they use water tanks from trucks with decent heat insulation. With some math and 16m3 tank you'll get close to 18kWh of stored energy for each degree Celsius of temperature rise for the water inside. If it was sand the energy per 1C would be ~7kWh.

Water has a lot of advantages when you want to put in and get out the heat energy. First - it will take more than twice the energy to heat up with 1C compared to sand with the same volume. This will result in a lower temperature for the heat transfer medium that you loop through the solar collector. This will increase the efficiency of the collectors. Second, the upper layer of the tank will always be with the highest temperature. This will ease heat extraction.

If you have concerns about maintenance - use inhibitors for bacteria growth and for metal corrosion. This is what I use in my water UFH system.

One of the advantages of using sand is that you can go higher temperatures compared to water, so you can use a smaller volume.

Using water is common in places where you have heating requirements and use wood since a large tank gives you a buffer (no need to keep a fire going all the time: efficiently burn in a short amount of time and store it), so it's possible to directly use this with solar (I do that with a heat pump).

Using water is common in places where you have heating requirements and use wood since a large tank gives you a buffer (no need to keep a fire going all the time: efficiently burn in a short amount of time and store it), so it's possible to directly use this with solar (I do that with a heat pump).

Mart Hale

New Member

- Joined

- Feb 4, 2020

- Messages

- 182

I was thinking ( which is a scary thing ) of building a cob oven insides with fire brick, inside then coating that with cob. Next with about 1 inch of cob on that create a pocket on top of the cob of dry sand. then in the sand put heating elements, then seal all of that in with cob..... Thus you could heat the thermal mass either by the heating elements or use wood heat.... May need chicken wire over the final pat to give it more stucture......No matter how you fire it, you're going to need a way of storing the heat in sand and insulating it so you don't lose all the heat - how will you do that?

MyK3y

Hack

I can share what people do here when we are talking about a storage tank for a lot of energy - they use water tanks from trucks with decent heat insulation. With some math and 16m3 tank you'll get close to 18kWh of stored energy for each degree Celsius of temperature rise for the water inside. If it was sand the energy per 1C would be ~7kWh.

Water has a lot of advantages when you want to put in and get out the heat energy. First - it will take more than twice the energy to heat up with 1C compared to sand with the same volume. This will result in a lower temperature for the heat transfer medium that you loop through the solar collector. This will increase the efficiency of the collectors. Second, the upper layer of the tank will always be with the highest temperature. This will ease heat extraction.

If you have concerns about maintenance - use inhibitors for bacteria growth and for metal corrosion. This is what I use in my water UFH system

The issue I have with using water is space and expense.

16cuM of water weighs 16 tonnes and physically is 2.5M on a side. A 200L /44gal drum is 875mm x 580mm and weighs 320kg full of sand (1.6kg/L for dry sand)

Logistically, I’m not getting that through the 750x750 access hatch under my house any time soon. Obviously this isn’t going to be the case for everyone.

The cost of a tank 2.5M on a side is significantly higher than a $10 drum and free river sand - I can’t find a 16,000L tank for under $1500. I can find 1cuM caged tanks for $250 second hand, but you would need 16 of them with the associated plumbing and heating element costs

Insulating a tank of 2.5M is significantly more expensive than insulating a steel drum 850mm high - smaller vessels can be more effectively insulated more easily.

All things being equal, water has a greater mass thermal storage capacity, but sand has a much higher volumetric storage capacity

1m3 of sand and water compared - from an ambient temp of 15C to max (assume max of 500C for sand):

H2O - you can store 85C x 4185J x 1000kg Joules before your water starts to boil = 355,725,000J - 98kWh

Sand - you can store 485C x 835J x 1600kg Joules = 647,960,000J - 180kWh

In my implementation, with a well-insulated 200L steel drum full of sand, raised to ~500C using an electric element will store 36kWh of heat - equivalent to running my panel heaters flat out for 5 hours at a grid cost of $12

So a real-world implementation gives sand a volumetric capacity nearly double that of water, at a significantly reduced cost and size.

My maths may be suspect, but it looks like in your comparison of 'effectiveness' you are limiting sand to a maximum of 100C and missing the increased mass storage of sand - 16m3 of sand weighs 25,600kg vs the 16,000kg of water and can be heated in excess of 500C

For your 16M3 tank that would store 2880kWh in sand

The same volume of water heated to 100C gives you 1581kWh of capacity.

Depending on your environmental requirements, sand batteries can be significantly more effective from an outright capacity as well as a price/performance standpoint.

Last edited:

Similar threads

- Replies

- 94

- Views

- 6K

- Replies

- 55

- Views

- 3K

- Replies

- 36

- Views

- 1K

- Replies

- 4

- Views

- 189