Lake country

New Member

- Joined

- Nov 3, 2020

- Messages

- 20

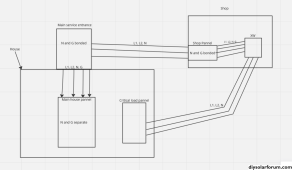

Does anyone know why on page 61 of the XW pro installation manual (ac grounding) it says you may not have to run a ground wire to your critical load panel if you are using dc grounding? This would be great for me because I have 3 wire feeder buried between my inverter and critical load panel.