My fields of study are electro-magnetic and metalurgy, so I'm shaky on electro-chemical...

Metallurgically, solder in SOME applications where high or constant vibration is not recommended.

Aircraft, submarines, anything that has constant High Frequency vibration will Work Harden wires right being the solder.

Wiring is bundled, stationary, then there is free wire that will vibrate/swing, solder keeps the wire strands from deforming and radius bending, and they can break off just behind the terminal.

This is bending the strands, work hardening the conductor,

In metalurgy we call it stress, fracturing the crystalline grains.

As crystals fracture, 'Slivers' break off, with wedge shaped sharp edges,

Those wedges are very efficient 'Jacks' and pry the grains apart until they fail.

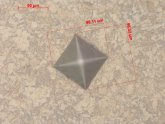

This is brass, but it's 70% or more copper,and the image is called a Micrograph.

The diamond shape punch mark is a hardness (cross sectional density) punch, and the mark is measured to determine how much the material deflects when pressure is applied (hardness, resistance against the force calibrated punch).

This sample has been mounted, polished down to 2 microns, acid etched & stained so you can see the crystals.

Polarized light filters are used to being details out in the image.

View attachment 2236

There is a reason I say to point the terminal down about 45 degrees, and STOP when the solder starts climbing the wire bundle.

Tinning up to the insulation line is recommended, but tinning INSIDE the insulation is a bad idea.

Gravity & Air pressure inside the insulation will 'Cap' the solder, the solder will be more or less a straight line, and hard/fixed conductor strands that can't move are a bad idea, it creates a Stress Line where all strands are forced to bend at the same spots over & over, work hardening the strands.

The benefits of properly soldering bare copper outweigh the negatives, particularly in DC wiring.

DC doesn't have the same rules of conduction AC has, DC is one way electron flow...

Resistance ANYWHERE accumulates & compounds.

(Skin Effect is why corroded aluminum AC power lines waste as much as 80% of production in transmission, and voltage is pushed instead of amperage)

Another benefit is environmental protection of the expensive copper and the time saved NOT having your system down while you tracked and replaced corroded wires and ruined terminals, particularly terminal to wire sockets you CAN'T see on visual inspection.

The ONLY way to track a corroded socket/cable corroded under the insulation is a Load Test.

1-1/2 volt resistance multimeter will not detect corroded conductors if there is even one strand still intact.

When a 2/0 cable won't conduct 35 amps, but shows no resistance since *Some* strands are intact, a load test is the only way to find it...

Solder simply seals up the exposed wires so acid/corrosive moisture can't enter.

View attachment 2238

There is no 'Skin Effect' with DC, only solid, internal contact conducts DC.

Solder increases that contact mass/area, particularly if it contains silver.

AC lines are melted/welded at terminus into a solid mass, the surface area of strands is what is important, while DC amp load is carried by mass, one solid conductor does best, but if you want to bend it, tightly packed fine strands puts more mass in the same size space and allows it to bend.

(One reason I recommend fine strand welding cable, it carries more amperage than the heavier strand 'Battery' cable in the same AWG size)

I go on & on about contact surface area, the 'Thickness' (conductor capacity) of heavy 'Neck' terminals instead of thin/hollow tubing terminals,

But when I started a 120 Watt panel was HUGE, Expensive and hard to find, every watt counted.

I was making due with leaky lead acid batteries that were short lived and expensive.

Having my cables heat up sucking Watts in do so taught me some hard & expensive lessons.

Since stationary solar batteries/DC connections aren't subjected to high frequancy vibration, and they will never conduct AC, there aren't any down sides.

In a vehicle, that bounces down the highway a few minutes/hours a day, consider battery cables are often cast/molded directly into lead terminals, the same as solder and take decades to fail, the lead/acid battery usually eating up terminals before conductor fails.

I would point out that oxy-torch actual silver is used for solder in the big welders & generators, train drive motors, etc.

Constant vibration 24/7/365 since 1900 (120+ YEARS!) In subway system generators in big cities.

The original Edison, Tesla & Westinghouse generators are still in use...

The original Tesla/Westinghouse generators at Hoover Dam just got their first rebuild around 2000, in continuous service all that time on silver soldered (pure silver) connections.

It's all entirely what you want to believe and how you want to do things.

In a camper/RV/trailer that can have moisture condensation I personally would solder and glue/heat shrink since condensed water will run down the cable directly into terminals.

If you check around the forum, you will find complaints about propane heat producing a LOT of moisture, and virtually all campers/RVs are propane heated.

Cooking produces a lot of moisture that has to condense somewhere...

A little solder and a little heat shrink goes a LONG way towards zero harness fails, I HATE chasing harness fails

.

Then we have to consider the electro-chemical end of things.

While metals will transfer and plate the opposite terminal, or even bond solidly with the other terminal in an IDEAL environment,

But a common oxygen environment is FAR from 'Ideal'!

Breathing oxygen (O2) and Ozone (O3) are bad enough in electrical connections, worse in DC connections,

Moisture (H2O) with a current running through it splits, the Hydrogen is separated from Oxygen (O) which immediately attacks the conductor material in the connection.

Anything trying to transfer from one terminal to another (ions, electrons) taking material with them instantly corrodes in the Oxygen (O) environment.

Something as simple as grease seals out moisture/oxygen and the connection sides live MUCH longer.

The grease is squeezed out anywhere the metals meet, but remains in what would normally be air spaces that would allow moisture into the connection.

This all assumes there isn't anything else in the air/moisture getting into the connection,

Sulfur (sulfuric acid), salts, all kinds of other stuff rides the moisture into that connection.

We all know what 'Salt Air' or salt on roadways does to metals, particularly where metals meet and create a weak (DC) battery called a 'Galvanic' reaction, the sheet metal simply corrodes away on car bodies at seams...

Throw a million times that DC current through that contact area, DC terminal to DC terminal, and the response is a million times greater.

Solder removes the air gap and increases the contact area PERMANENTLY.

Even a coat of grease in the air spaces reduces that potential for 'Air' and moisture to enter and the corrosion process is stopped or slowed down by about a million times.

There is a reason electrical insulation are non-oxygen permeable...

The. Consider thermal expansion...

Normal heat/cool cycles, hot day & cool, most nights.

Or duty cycle, heavy loading heat and light load cool down.

Everytime the cable heats, the air expands, when it cools it draws in moist air and the moisture condenses on the conductors.

It's the same principal when gas tanks & oil pans condense moisture out of the air.

Blind socket terminal ends keep moisture/corrosives from entering the cable/terminal socket and cable insulation.

Grease, solder & glue/heat shrink do the same job even though some people argue against it, it's just common sense.

It's application, since our solar batteries are DC, and since they don't vibrate constantly,

And since this isn't very fine wire that's unsecured and swings around with that vibration.

These cables are heavy, and like battery cables in vehicles, they aren't subjected to high frequancy vibration, but have bare copper (not tinned wire) exposed constantly to oxygen & moisture rich environment.

In the solar/RE, bare copper, DC current APPLICATION, I find soldering has few drawback and several benefits.

Make up your own mind, it's *Your* system, do what you want to.

It's your decision, I'm just passing along what I've learned through education & experience, use it if you can or want to...